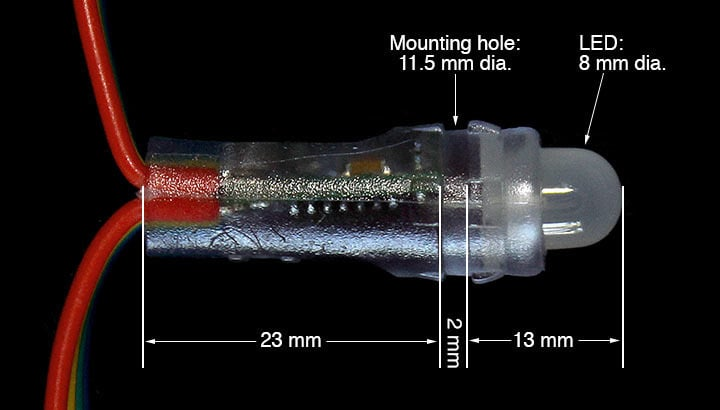

I’m in the process of replacing all my single-color christmas lights with addressable RGB LEDs, but the 12mm “bullet” form factor of them is different from the traditional incandescent mini lights, the 5mm wide angle LEDs, etc.:

You’d think they’d make C6/7/9 bulb covers that attach to them, but I have yet to find any for sale, anywhere. As such, I want to 3D print some, along with 12mm bullet pixel-sized replacements for my snowflake lights:

What’s some good filament I can get that will be reasonably clear and stay that way (without yellowing or getting too brittle) for several years’ worth of Christmas seasons, despite UV/rain/cold exposure?

(Bonus question: anybody know a good way to model the facets in those “strawberry” lights? The C7 bulbs on Thingiverse, such as this one, are all smooth, LOL.)

Edit: by the way, to be clear (pun intended): I don’t need optical clarity like the lens guy; scattering the light is fine. (In fact, doing that on purpose is kind of the point of modeling a faceted C7 bulb instead of a smooth one.) I just want to make sure that whatever part of the filament that doesn’t manage to be transparent is white, not tinted some dingy color.

I do happen to have some Inland “natural” PLA laying around and did a test print in that. It’s not too bad – only a little bit yellow at the wall thickness I’m using – but I fear for how it will hold up over time.

Hmmm, I would usually go for ASA for anything outside, but searching around for transparent ASA comes up empty… I guess maybe transparent ASA isn’t a thing? Too bad, since you could smooth it with acetone to make it even lower opacity. You could also look at Polycarbonate and PETG, which I know can be made transparent, but those might yellow a bit after a few years.

I’m interested in other people’s thoughts. Definitely a good question!

Agree, Asa ideal, but I’ve never seen it in transparent varieties. I’d actually try PVB - probably some of the nicest transparency. Might not hold up well outdoors, but I’d give it a shot and then go to PETG if it falls apart.

PVB filament is giving me sticker shock ($36 for 750g), as is polycarbonate ($30 for 1kg).

I think PETG is probably the way to go. Anybody have strong opinions between

?

I’ve tried Overture, Creality, and Inland (all black though, not transparent) and Overture printed the best for me (at least for functional parts where I cared about print quality and tolerances). Inland’s PETG+ and High Speed PETG was even better though.

Oh, another thought - you could use a UV blocking clear coat such as this on your print. I still would avoid PLA though, since it might get hot in the sun. It would be important to get a complete coat with that spray, even between layer lines. You might want to think about using a clear resin if you have access to a resin printer, since it would have a much smoother finish before being coated.

Yeah, I’ll probably do a clear coat.

The thought of using a resin printer had crossed my mind, as well. It wouldn’t work for the snowflakes – those would be too large for any but the most gigantic resin printers – but it would be optimal for the C7 bulbs. That said, I literally just bought a new filament printer (just an Ender 3, not a fancy Bambu or anything – until now I was making do with a MP Mini!) and buying two printers at the same time makes my bank account sad.

Also, I’m not sure the material resin printers use is all that great at resisting UV either.

Oh 3d printer resin is absolutely not UV resistant - resin printers use UV light to solidify the resin at each layer, and exposing a print to too much UV light after printing can cause UV burn, similar to a thermoplastic.

Coating the print in a UV resist clear coat should prevent UV light from reaching the print itself, and preventing the burn; think of it as sunscreen for your print 😉